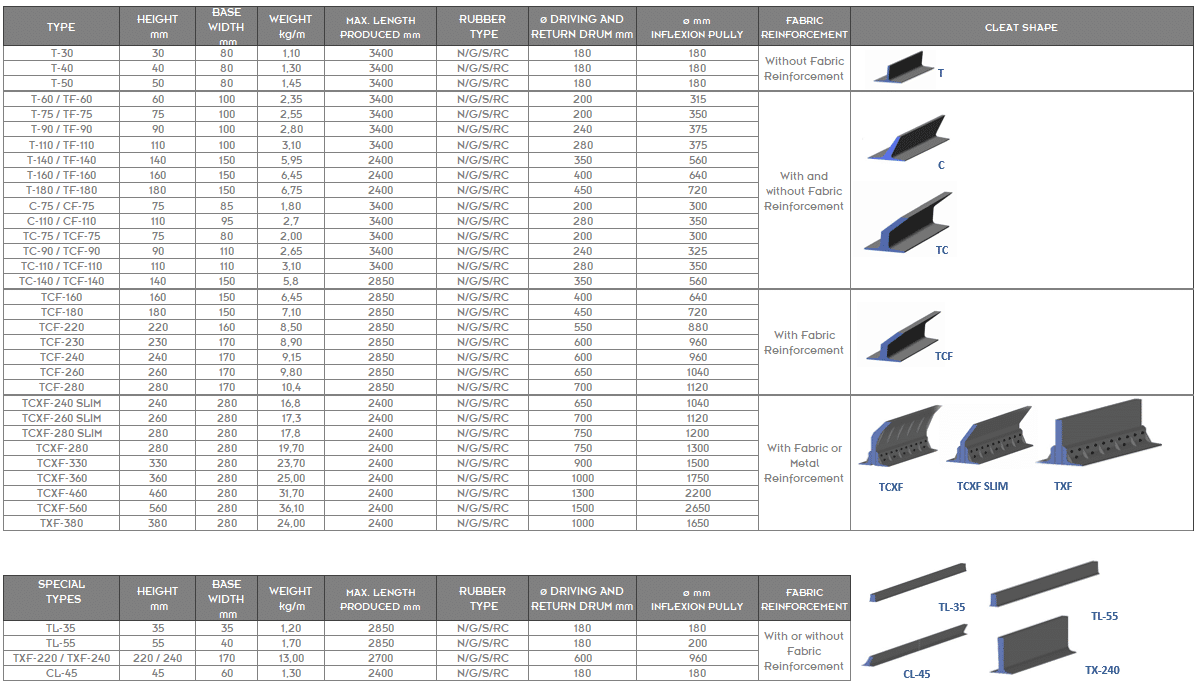

In order to determine the dimensions of cleats when designing a Beltsiflex®, belt, we use the same formula that applies in the volumetric calculations of a conventional belt. Nevertheless, we must consider where the materials to be transported are to be placed within the carrying area formed by the cross cleats and the sidewalls; the grain size of the product will be of vital importance for good operation and functionality of the installed system.

For high granulometry products:

With the aim of avoiding the loss, leak or projection of material during transportation or accidents due to obstruction, it is necessary to pay attention to three selection criteria, always dependant on maximum granulometry. These criteria will always be the minimum measures to beincrease according to the transport capability desired.

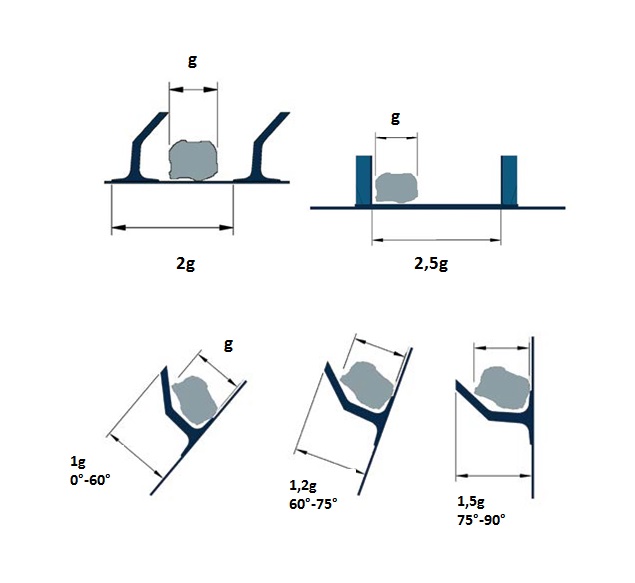

- Spacing between cleats:

The minimum distance between cleats must be twice the maximum grain size.

- Cleat width:

The width of cleats must be at least 2.5 times the maximum grain size.

- Cleat height:

As for the minimum height of the cleats, two aspects must be considered when making a choice:

a) Once again, maximum grain size.

b) The angle of inclination of the belt:

It is recommended that you follow these criteria:

Angle of inclination: 0 ÷ 60º

Cleat height: 0.75 ÷ 1.0 x grain size (“g”)

Angle of inclination: 60 ÷ 75º

Cleat height: 1.0 ÷ 1.2 x grain size (“g”)

Angle of inclination: 75 ÷ 90º

Cleat height: 1,5 x grain size (“g”)

The height of the sidewall must always be in excess of between 10 and 20 mm than of the selected cleat.

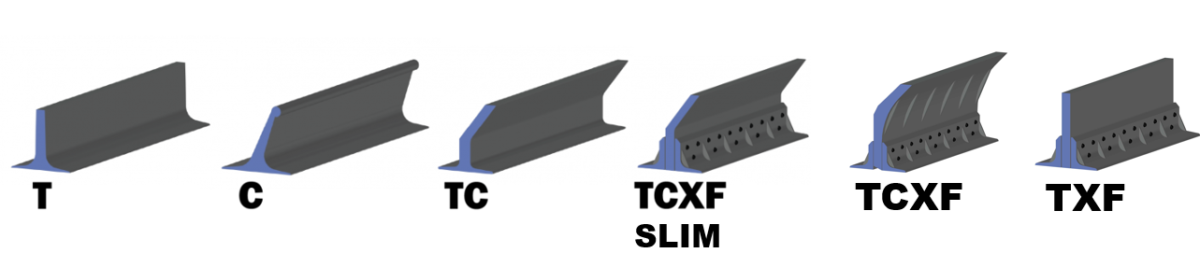

For vertical belting, “TC” or “TCXF” type cleats must be used.

Products with low grain size:

The material conveyed within the pockets of the belt never takes up 100% of their carrying volume. When calculating the capacity of the pockets, we must always consider a 75% load, as indicated in the attached figure. When the granulometry of the materials to be carried is low, the shortest possible spacing between cleats should be selected in order to achieve maximum efficiency; depending on the type of cleat chosen, the spacing will be different.

The necessary belt width is determined according to belt dimensions, height and desired load capability.