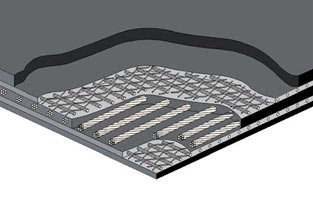

CROSS STABILITY BELTS

SIBAN has developed a cross stability rigid belt base for the construction of the Beltsiflex® Belts, necessary for the system performance optimisation. We can offer different constructions to suit the specifications of each installation.

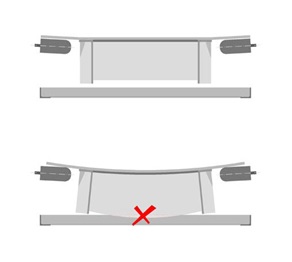

The use of cross stability rigid belts offers significant advantages: Provides better support on the return strand.

Avoids the wear and tear of sidewalls and cleats.

Prevents the crowning of the carrying surface at deflection points.

Prevents the loss of driving power.

It is only possible to use a standard belt with no cross stability in small constructions without deflection points.

In order to adapt Beltsiflex® Belts to the characteristics of the materials to be transported, we offer a variety of rubber compounds used in the covers of the base belts, all manufactured according to DIN standards.

RUBBER QUALITY:

N: Normal Quality

G: Oil Resistant Quality.

S: Flame Retardant Quality.

HR: Heat Resistant Quality up to 150ºC

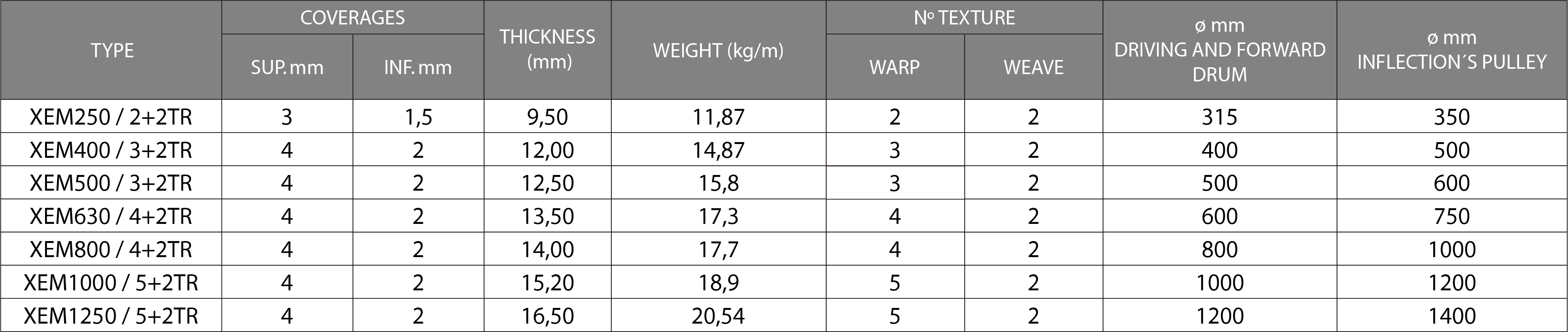

TYPES OF CROSS STABILITY BELTS

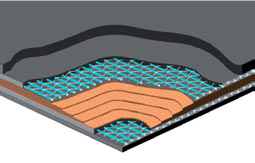

Manufactured with fabric plies, they are produced using the same Beltsiflex® elevated belting systems technology. They provide greater stability than the commonly used EP fabrics (polyester – nylon) by adding to these one or two monofilament fabrics to achieve the rigidity most suitable for the belt’s characteristics.

All XE are manufactured in the following rubber compound varieties:

N: Normal Quality

G: Oil Resistant Quality.

S: Flame Retardant Quality.

HR: Heat Resistant Quality up to 150ºC

MAXIMUM WIDTH IN STANDARD MANUFACTURING: 2400 mm

We manufacture belts with different covers and widths other than standard ones on request.

*The indicated diameters are merely for reference, being necessary to calculate them for the specifications of each specific project.

*The established diameters are illustrative being necessary the calculation adapted for each project.

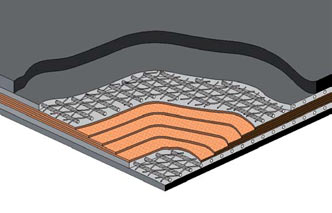

Manufactured with fabric plies, they are produced using the same Belsiflex® XE type technology but differ from this in that their rigidity is achieved by inserting one or two metal cords across the belt.

This type of belt is recommended when the rigidity needed is not satisfied by the XE type. It is particularly indicated for the transportation of large productions and heavy duty applications requiring significant width dimensions.

This belt differs from type XC in that it also incorporates metal cord tensioning along the belt and is used for the construction of big installations where the belt, not only supports high productions, but is also of large dimensions. The elongation values of this type of belts are nearly null.