Filler material for splicing. Its formula provides this rubber with excellent

adherence properties and tearing flexibility, which gives the joints very

good performance, even in the toughest belt situations.

It is placed between the belt’s fabrics using a suitable thickness according

to the characteristics of the belt to be joined. Supplied in two thicknesses:

- Calendering at 0.8 mm and identified by Red plastic

- Calendering at 1.6 mm and identified by Blue plastic

Both thicknesses are supplied in rolls of 15 kg in the following qualities:

Normal Quality, Oil Resistant Quality, Flame Retardan Quality, Heat Resistant Quality.

High adhesion joint rubber

Normal adhesion rubber

Metal bonding rubber

Supply material with properties for the belt conveyor area. It is supplied in thicknesses from 2 mm to 8 mm in rolls of 15 kg.

Identified by yellow plastic in the followings qualities:

- Normal Quality

- Oil Resistant Quality

- Heat Resistant Quality

- Flame Retardant Quality

Identified by yellow plastic.

The Hot splicing kit can be offered in diferent qualites by Siban Peosa, S.A:

Normal Quality, Heat resistant quality, Oil resistant quality, Flame Retardant

quality and white.

These qualities can be offered for Textile and Steel cord belts. The HOT SPLICING KIT consists of:

- Cover Rubber, filler material with specific characteristics for the

running areas of the conveyor belt.

- Uncured interply rubber, with outstanding properties of adhesion,

tear resistance and flexibility providing a really good performance

to the joints.

- Rubber solution, the suitable and necessary product for hot

vulcanized conveyor belts.

Depending on the width of the conveyor belt, the client will be provided with the appropriate materials for making the splicing kit.

“ELASTO-DISOL” is the ideal rubber solution product required for hot

vulcanizing, both for conveyor belts and for the rubber coating of rollers

and drums. Given its characteristics, we recommend its use for any

application requiring hot vulcanising of rubber-metal, rubber-rubber,

rubber-fabric. This product comes in three formats:

- 25 litres can

- 5 litres can

- 1 litre can

“ELASTO-DISOL” is perfectly labelled together with usage instructions,

to make it easy to use and to prevent any accidents from improper usage. Supply in three different types based on their application:

- Elasto-Disol Natural

- Elasto-Disol Neoprene

- Elasto-Disol White

Suitable for cold bonding of rubber conveyor belt, fabric and steel. Also for

the rubber covering of drums, rollers and chute linings. We recommend

ELASTOGLUE 2022 for any application in which it is necessary to bond

rubber to metal, rubber to rubber & rubber to fabric.

In order to activate the bonding process, Elastoglue must be mixed with 10

% of RETICULANTE 2022 (hardener). This product is supplied in:

- 700g cans + Hardener

- 3kg cans + Hardener

ELASTOGLUE is clearly labelled with application instructions and the

necessary warnings, in order to facilitate its usage and to avoid the

possible mishaps that incorrect usage could create.

Our experience has led us to manufacture a wide variety of special patches

for repairing rubber conveyor belts. These patches are available in different

types (with or without fabric reinforcement), different shapes (round,

diamond shaped and in strips) and different sizes to fit the repair area.

| TYPE | WITH/WITHOUT REINFORCEMENT | MEASURE |

|---|---|---|

| Patch Strip | Whitout Reinforcement | 70 x 10.000mm |

| 100 x 10.000mm | ||

| 150 x 10.000mm | ||

| 220 x 10.000mm | ||

| Patch Strip | Whit Reinforcement | 70 x 10.000mm |

| 100 x 10.000mm | ||

| 150 x 10.000mm | ||

| 220 x 10.000mm | ||

| Patch Diamond | Whitout reinforcement | 135 x 160 mm |

| 200 x 260mm | ||

| 270 x 360mm | ||

| 450 x 470mm | ||

| Diamond Patch | With reinforcement | 135 x 160 mm |

| 200 x 260mm | ||

| 270 x 360mm | ||

| 450 x 470mm |

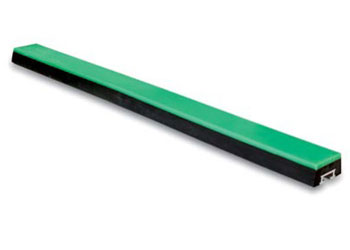

- The impact bar is an important cushioning part.

- It eliminates material loss on the conveyor belt and protects against

possible damage caused by the impact of sharp objects.

- Used in belt conveyor material guiding groove, blanking point

below the belt.

- Outstanding capability to absorb impact and low friction

coefficient.

| SPECIFICATION | HIGH (mm) | WIDTH (mm) | LENGHT (mm) |

|---|---|---|---|

| 50 x 100 x 1500mm | 50 | 100 | 1200 |

75 x 100 x 1500mm |

75 | 100 | 1500 |

50 x 100 x 1200mm |

50 | 100 | 1200 |

75 x 100 x 1200mm |

75 | 100 | 1200 |

Selección del modelo :

| Belt Width (mm) | Number of Bars | Distance | Roller widt (mm) | |||

|---|---|---|---|---|---|---|

| Izquierda | Centro | Derecha | Lados | Centro | ||

| 550 | 1 | 2 | 1 | 50 | 0 | 200 |

| 650 | 2 | 2 | 2 | 25 | 25 | 250 |

| 800 | 2 | 3 | 2 | 50 | 5 | 315 |

| 1000 | 3 | 3 | 3 | 25 | 25 | 380 |

| 1200 | 3 | 4 | 3 | 55 | 20 | 465 |

| 1400 | 4 | 5 | 4 | 45 | 7 | 530 |

| 1600 | 5 | 5 | 5 | 25 | 25 | 600 |

| 1800 | 5 | 6 | 5 | 25 | 10 | 670 |

| 2000 | 6 | 6 | 6 | 20 | 25 | 750 |

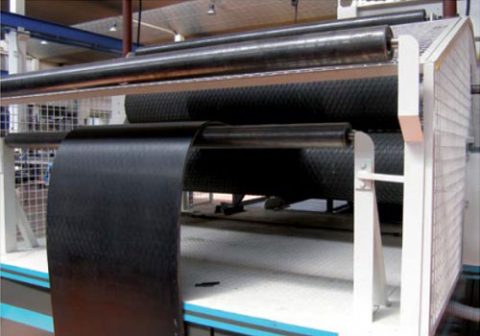

Our production line for the manufacturing of extruded rubber profiles guarantees a quick response that meets our client’s needs.

We can manufacture any type of profile made to order using the most suitable material: wear resistant, high temperature resistant, oil resistant, high tensile strength materials etc.

The fields of application of our products are wide ranging, including any type of profile found in variuos sectors such as:

Construction, automotive industry, mining, electronics, telecom, pharmaceutics, engineering, transport, maritime sector, capital goods…

Siban manufactures all kind of rubber moulded goods. Our industrial facilities are suitable to answer all our customers’ demands. Siban’s wide range of industrial equipments ensures the company is able to manufacture goods to many requirements, qualities, sizes or quantities.

Our ongoing R&D and working together with our clients, allows us to develop a complete and varied range of formulas, all capable of adjusting to all kind of industrial uses. According to our customers´ needs and based on the formulas investigated and researched in our laboratories, we make our own mixtures using all kinds of rubber. Covering the drums with rubber increases the friction coefficient between the conveyor belt and the drum, even under the worst operation conditions (soaked/wet).