Longitudinally along the belt, 7×7 or 7×19, according to the diameter necessary to obtain the required resistance of the belt. Structures with metal breakers, depending on their applications, might be added to the covers of the belt. Belts with Fleximat® mesh.

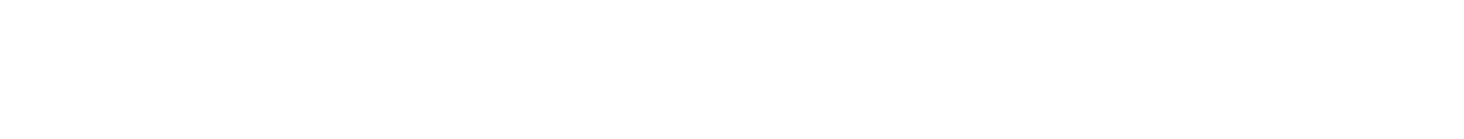

“ST” TYPE STEELCORD BELTS

They incorporate steelcord tensioning longitudinally along the belt, and are normally used in large mining installations. They are often of great dimensions in length and capacity.

The steel cord’s stress resistance makes this type of belt ideal for the mentioned applications. Furthermore, these belts also provide us with several additional advantages:

- This type of belt has very low elongation values, thus facilitating the construction of installations many kilometres long.

- More fexible than their equivalent with fabric reinforcement, they require drums with smaller diameters.

- They have greater perforation resistance. They are not subject to deformation either due to discontinuous heavy loads or external agents such as heat, cold, and humidity, thus ensuring the belt moves in a straight aligned fashion.

- They admit rubber coatings of any required thickness. Breakages such as longitudinal slitting, damaged sides, or holes are easily repaired by hot vulcanisation, which guarantees the belt’s long life.

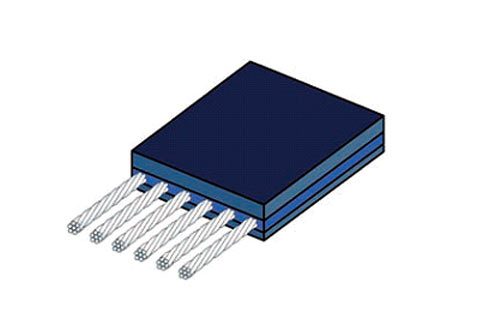

BELTS WITH FLEXIMAT® MESH

In these belts, in addition to the advantages offered by Steelcord belts, they also incorporate transversal steelcord reinforcement, which multiplies their properties for the toughest working conditions.

They offer extraordinary resistance to impact and to the action of very sharp materials. They are manufactured with a metal wire mesh insertion both as tensioning ply (longitudinal) and weave (transversal).

They can incorporate one or two layers of steelcord tensioning ply and weave, which may be:

- Rigid: Indicated for special applications as part of the Bandaboard system or in installations with bucket elevators.

- Flexible: Suitable for conveying aggressive materials, they are highly resistant to impacts and slitting.

- IW: 1 mesh

- SW: 2 meshes (top and bottom face)